November 4, 2025

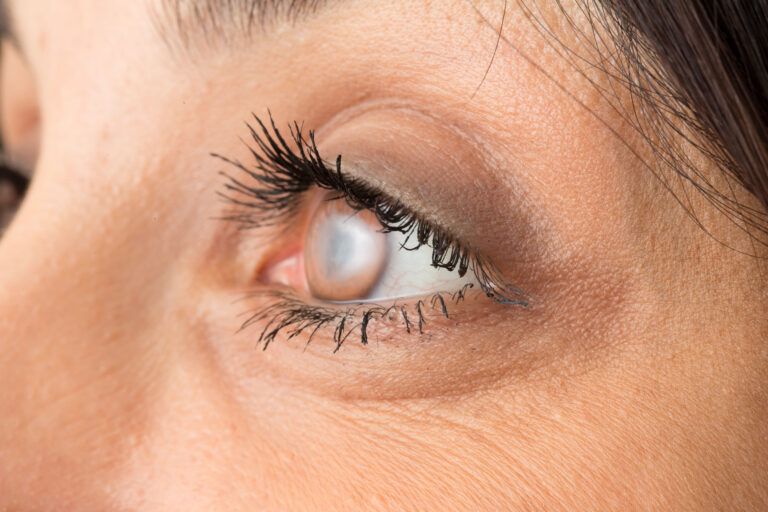

Phaco machines are vital to modern cataract surgery, allowing ophthalmologists to deliver precise, efficient procedures with minimal trauma to the eye. These systems combine the flow of fluids, ultrasound energy, and advanced software to break down and remove the cloudy lens that causes vision impairment. As the number of cataract surgeries grows worldwide, maintaining dependable performance from your equipment becomes increasingly essential. According to the Cleveland Clinic, about half of all people who live into their 90s will need cataract surgery, underscoring how crucial it is for surgical centers to have well-maintained machines ready for every case.

However, even the most advanced equipment requires consistent care to stay in peak condition. Small issues that go unchecked can evolve into costly repairs, surgical delays, or even risks to patient safety. Regular phaco machine maintenance helps identify and resolve problems early, keeping your surgical schedule running smoothly and your results consistently excellent. Recognizing the signs of wear or malfunction is the first step toward preventing downtime and preserving your investment.

1. Inconsistent Liquid Flow During Surgery

When the flow of liquid becomes unpredictable—such as fluctuating irrigation pressure or erratic aspiration—it’s a clear signal that you may need to consider phaco machine maintenance. These inconsistencies can make it difficult for the surgeon to maintain a stable anterior chamber, which can increase the risk of complications during cataract removal. Even small variations in vacuum levels or flow can impact visibility and control, turning a routine procedure into a stressful one.

In many cases, inconsistent liquid flow stems from worn-out tubing, clogged filters, or problems with the internal pump. Regular phaco machine maintenance includes inspecting these components, testing fluid flow, and replacing parts that show early signs of wear. Preventive care not only restores stability but also helps preserve the delicate balance between aspiration and irrigation that’s so critical for patient safety.

Additionally, technicians performing routine service can use diagnostic tools to measure flow consistency, pressure response, and vacuum recovery rates under simulated surgical conditions. These tests help identify issues that might not be visible during standard operation but could compromise real-time performance in surgery. By catching small calibration drifts or declining pump efficiency early through phaco machine maintenance, you can maintain a steady flow of liquid, enhance surgical precision, and prevent unplanned delays in your operating schedule.

2. Unusual Noises or Vibrations

A healthy phaco machine should operate with minimal noise and smooth vibration levels. If you notice strange sounds—like grinding, rattling, or high-pitched whines—it could point to issues within the handpiece or internal drive systems. These noises often develop gradually, making them easy to ignore until performance noticeably declines. However, they’re often the first clue that components are loosening, misaligned, or beginning to fail.

Addressing these symptoms promptly during phaco machine maintenance can prevent extensive mechanical damage. Technicians can check bearings, couplings, and transducer assemblies to identify the root cause. Keeping the equipment quiet and balanced not only improves reliability but also enhances the surgeon’s comfort and focus during delicate procedures.

3. Inaccurate Power Delivery

When the ultrasound power output doesn’t match the settings displayed, your phaco machine may be miscalibrated or suffering from internal electronic faults. This can result in inconsistent lens fragmentation or extended procedure times, both of which can compromise patient outcomes. Precise power delivery is crucial to emulsifying the cataract efficiently without damaging surrounding ocular structures.

Routine calibration as part of phaco machine maintenance helps restore accuracy and prevent these variations. Technicians use diagnostic tools to test output levels and adjust them according to manufacturer standards. They also check the handpiece’s transducer for wear or electrical degradation, ensuring that every watt of ultrasonic energy is delivered safely and effectively.

Moreover, inconsistent power delivery can place additional strain on the surgeon, who may need to compensate for underperforming energy levels during delicate maneuvers. Over time, this can increase fatigue and reduce surgical efficiency. By performing thorough phaco machine maintenance, clinics can ensure that power delivery remains consistent, giving surgeons the confidence to focus on precision and patient safety without worrying about equipment performance.

4. Leaks or Moisture Accumulation

Any sign of fluid leakage near tubing connections, seals, or internal compartments is a serious concern. Even small leaks can disrupt pressure stability and introduce air into the system, which affects aspiration performance. Over time, moisture can also corrode internal metal parts or damage sensitive electronics, leading to expensive replacements.

During routine phaco machine maintenance, technicians thoroughly inspect fluid pathways, connectors, and gaskets for signs of deterioration. They clean and reseal any vulnerable joints and replace worn components as needed. Detecting moisture early prevents long-term damage, helping to maintain both safety and performance consistency throughout the surgical day.

5. Software or Display Malfunctions

Modern phaco machines rely heavily on integrated software and touchscreen displays for precise control. When those systems begin freezing, displaying errors, or lagging between commands, it disrupts surgical flow and can undermine confidence in the equipment. These malfunctions can also indicate outdated firmware or electrical issues affecting the control interface.

Comprehensive phaco machine maintenance includes software diagnostics, data integrity checks, and updates to the latest manufacturer versions. Keeping the system’s software current not only resolves glitches but can also introduce performance improvements and new safety features. Reliable, responsive displays help surgeons make quick adjustments during procedures without hesitation or distraction.

6. Frequent Error Codes or Alarms

Error messages and alarms are built into phaco machines to alert users to potential malfunctions. However, when those alerts become frequent or unexplained, they shouldn’t be dismissed. Repeated alarms may point to pressure inconsistencies, power faults, or calibration drifts that can affect surgical precision. Ignoring these signals increases the risk of unexpected shutdowns during operations.

By scheduling regular phaco machine maintenance, technicians can access diagnostic logs to interpret and correct the causes behind these alerts. They can recalibrate sensors, replace faulty modules, or perform software resets as needed. Addressing these issues proactively prevents interruptions and helps maintain compliance with safety and performance standards.

7. Decline in Suction Efficiency

A decrease in suction strength or slower lens fragment removal often means your vacuum pump or aspiration tubing is compromised. This can extend surgical times and create difficulty maintaining a clear field of view. Declining suction efficiency can also be caused by minor obstructions, worn seals, or malfunctioning sensors that regulate flow.

Phaco machine maintenance involves cleaning or replacing tubing, testing pump performance, and checking for leaks or clogs within the aspiration system. Maintaining proper suction ensures that lens material is removed efficiently and the eye remains stable throughout the procedure. The result is smoother operation, faster surgery times, and improved patient safety.

Your phaco machine is the backbone of your cataract surgery practice, playing a vital role in restoring patients’ vision and maintaining your clinic’s reputation for excellence. Recognizing warning signs such as inconsistent fluid flow, software errors, or reduced suction efficiency allows you to address problems early before they affect outcomes. Consistent phaco machine maintenance not only preserves performance but also protects patients, surgeons, and your overall investment. By scheduling regular service with MEDiSURG and staying alert to subtle changes, your surgical suite can continue to operate safely and efficiently for years to come—helping countless patients experience the world through clear eyes once again. Get started today by reaching out to us for a quote on your next preventive maintenance request!

The post 7 Signs Your Phaco Machine Needs Maintenance appeared first on MEDiSURG.