December 1, 2025

In the world of ophthalmic surgery, patient outcomes are the top priority. However, behind every successful cataract, retinal, or LASIK procedure lies a network of highly sensitive instruments. Neglecting eye surgery equipment maintenance can have far-reaching consequences, impacting both patient safety and operational efficiency. These devices are engineered with precision components that require careful calibration, regular inspections, and timely servicing to perform consistently.

Even minor malfunctions can lead to delays, compromised surgical accuracy, or unexpected downtime during procedures. Beyond immediate surgical risks, failing to maintain equipment properly can accelerate wear and tear, reduce the overall lifespan of costly instruments, and increase long-term operational expenses for the facility.

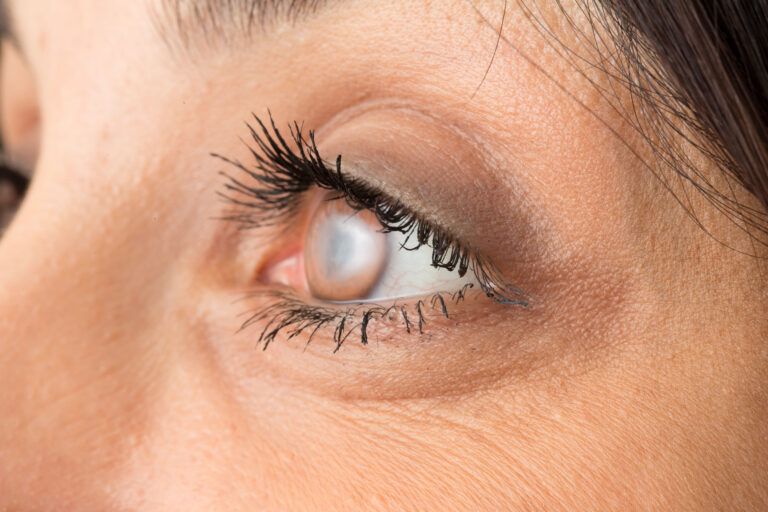

Recognizing the Risks

Many surgical centers may view skipping eye surgery equipment maintenance as a way to save money, but the risks are substantial. Equipment like phacoemulsification systems and vitrectomy platforms depends on precise calibration and flawless operation. Without regular care, pumps, sensors, and motors can fail unexpectedly. When systems falter mid-procedure, the consequences affect both patients and the facility. Delays, cancellations, and compromised surgical outcomes can damage your reputation and result in revenue loss.

In addition, malfunctioning equipment may require surgeons to improvise, which can increase stress levels in the operating room and reduce overall efficiency. Even small inconsistencies in equipment performance can accumulate, creating a cascade of minor errors that undermine surgical precision. Ultimately, ignoring maintenance is a gamble that can affect both lives and the financial health of your practice, highlighting the critical need for preventive care.

Understanding the Financial Consequences

On the surface, forgoing eye surgery equipment maintenance might appear to reduce costs. However, deferred maintenance often leads to much higher expenses in the long run. Emergency repairs are far more expensive than scheduled preventive maintenance. When a system breaks down, critical modules may need replacement, special parts may be required, and expedited service fees can quickly add up. The unavailability of equipment also translates into lost surgical volume, underutilized staff, and missed revenue.

Poorly maintained machines degrade faster, forcing premature replacement and creating additional capital expenses. Beyond direct costs, unexpected breakdowns can also affect insurance claims, liability considerations, and patient trust. By avoiding preventive maintenance, a practice risks compounding financial pressures while losing control over budget predictability. Neglecting routine care is essentially trading predictable costs for unpredictable losses.

Aligning Maintenance With Trends

Maintaining surgical equipment is increasingly critical in a market that continues to expand. According to Fortune Business Insights, when it comes to cataract surgical devices, North America is expected to rank as the second-largest revenue-generating region for cataract surgical devices by 2026. The growth in demand for cataract procedures means more surgeries, increased usage of equipment, and greater stress on machines. Facilities that prioritize eye surgery equipment maintenance are better positioned to handle higher surgical volumes, maintain patient safety, and remain competitive in a growing market.

Additionally, as surgical centers adopt new technologies and instruments to meet evolving standards, regular maintenance ensures seamless integration of upgrades. Neglecting maintenance in a rapidly expanding field can leave practices behind, struggling to meet demand and unable to keep pace with technological advancements.

Evaluating the Operational Risks

The operational risks associated with deferred maintenance go beyond finance. Equipment that hasn’t been routinely maintained can exhibit unstable fluidics, faulty foot pedals, handpieces with internal malfunctions, and calibration drift. These issues compromise precision and reliability during surgery. Additionally, software errors or hardware failures may interrupt procedures, causing delays or forcing conversions to alternative methods.

Physical wear on motors, connectors, and seals can create safety hazards and increase the likelihood of unexpected breakdowns. The operational strain on staff is also significant; technicians and surgeons may need to troubleshoot under pressure, creating an environment where mistakes are more likely. Without proper maintenance, even minor operational issues can cascade into larger disruptions that reduce efficiency and impact patient satisfaction. Routine eye surgery equipment maintenance mitigates these risks, ensuring that systems remain accurate, reliable, and safe for every procedure.

Understanding the Benefits

Partnering with a specialized provider like MEDiSURG transforms maintenance from a reactive task to a strategic advantage. MEDiSURG focuses exclusively on ophthalmic surgical equipment, including phaco, vitrectomy, microscopes, and lasers. Unlike general medical equipment companies, their technicians understand the unique requirements of eye surgery systems. This expertise ensures high-quality maintenance that extends equipment lifespan and reduces the likelihood of unexpected downtime. By offering flexible on-site service, remote consultations, and weekend preventive maintenance, MEDiSURG adapts to the operational needs of busy surgical centers.

Their comprehensive training programs empower staff to operate and maintain systems effectively, while detailed service reports provide insight into equipment health and risk management. Partnering with a specialist also facilitates access to spare parts and refurbished components when needed, helping practices minimize delays and maintain operational continuity. With a specialized partner, eye surgery equipment maintenance becomes a predictable, manageable, and cost-effective component of surgical operations.

Building a Preventive Maintenance Culture

Creating a culture that prioritizes preventive care is essential for long-term success. Scheduled maintenance for every major system should be non-negotiable and integrated into the annual operational plan. Training programs, such as those offered by MEDiSURG, help surgical staff and biomedical engineers understand the nuances of phaco, vitrectomy, and laser systems, enabling them to identify early warning signs of equipment wear.

Monitoring performance metrics, including error codes, foot pedal responsiveness, and fluidics stability, allows for proactive intervention before a minor issue becomes critical. Standardizing maintenance protocols for cleaning, calibration, and servicing ensures consistency and accountability. When preventive maintenance is embedded in everyday practice, staff develop a stronger sense of responsibility and confidence in their equipment.

Emphasizing the Strategic Payoff

Prioritizing eye surgery equipment maintenance offers long-term strategic benefits. Properly maintained equipment has a longer lifespan, reducing the need for premature replacement. Consistent performance ensures safer surgical procedures, protecting both patients and the reputation of the facility. Emergency repairs and downtime are minimized, allowing the surgical suite to operate efficiently and predictably.

As the cataract surgical device market continues to expand in North America and globally, maintaining equipment readiness positions surgical centers to handle growth effectively. Beyond operational benefits, reliable equipment can support higher patient throughput and improve financial performance.

Integrating Maintenance Into Everyday Practice

Routine eye surgery equipment maintenance shouldn’t be viewed as a separate task but as an integrated part of everyday operations. When maintenance becomes part of the workflow, technicians and surgeons develop a heightened awareness of equipment status. Simple habits, such as visual inspections, calibration checks, and recording performance metrics, contribute significantly to system longevity.

Partnering with MEDiSURG ensures that these practices are supported by expert guidance, detailed service records, and timely intervention whenever needed. Integrating maintenance into daily routines also fosters a proactive mindset among staff, helping them anticipate issues before they escalate.

Skipping routine eye surgery equipment maintenance may appear to save money in the short term, but the hidden costs, in financial, operational, and safety terms, are far greater. Emergency repairs, lost surgical volume, and compromised patient outcomes all underscore the importance of preventive care. The expanding North American cataract surgery market highlights the need for reliable, high-performing equipment to meet growing demand.

Partnering with a specialist like MEDiSURG ensures that your ophthalmic systems remain precise, safe, and dependable. Don’t leave your surgical success to chance. Schedule your next eye surgery equipment maintenance appointment with MEDiSURG today and protect both your patients and your investment.

The post The Hidden Costs of Skipping Routine Eye Surgery Equipment Maintenance appeared first on MEDiSURG.